A mechanical device is necessary to secure two units in an industrial job. Adding up a toggle latch to your toolbox can finish a task quickly. It aims for the workers’ safety together with all the tools for specific uses.

This post will discuss the components of a toggle latch to better understand how it works. It also includes some tips to help you choose the right device based on your requirements.

Different Features of a Toggle Latch

Buying a toggle latch is easy knowing the following components:

- Device’s Grip

Select a toggle latch with a longer handle. The reason behind this is it increases the force needed to secure the latch over the center. Likewise, consider an elastic handle to advance a non-slipping grasp while utilizing the device. It ought to be not difficult to control and not cause wounds among the laborers.

- Adjustable

The tool’s arm length will enable a specific tension, so an adjustable feature can help. Each task may vary on the amount of tensile strength needed which is responsible for securing the latch.

First, you need to adjust the screw arm, specifically its length to acquire enough force to position the latch. An added force is required when operating a toggle latch with a shorter screw arm. Make adjustments until the latch is fully secured.

- Shape Designs

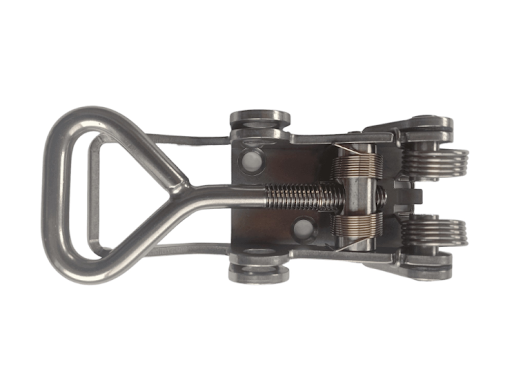

Once the latch is secured, the next thing to do is to connect the loop with the catch plate. The process will vary due to various shape designs of the loop and the catch plate. It could be oval, triangular, or a T-bar. The choice depends on the user’s requirements but the triangular design is the most versatile among the options.

- Friction

Some toggle latches are made of a friction ring for added security. It helps the screw arm to be in position while making adjustments. This will stop the risk of accidents when rotating the device.

- Safety Catch or a Padlock

A latch failure can possibly occur even after securing the device which may result in greater damage. However, a safety catch feature is added to keep the device in place without harming anyone. This is among the most significant parts of a toggle latch that can turn industrial works less risky.

Some models use a padlock instead to stop the latch from decoupling at any time. Either way is a good choice which the purpose is to increase protection among workers.

- Versatility

A toggle latch comes in different sizes and shapes to be suitable for various applications. It is ideal for fixing items apart from industrial jobs, such as automobiles, campers, and pieces of machinery.

A Quick Guide When Buying a Toggle Latch

Here is a list of factors you should consider in getting the right toggle latch for your needs:

- Types of Toggle Latches

Toggle latches have many kinds which are designed for light-duty to super heavy-duty applications. Hence, choosing a latch that you think is perfect for your needs is crucial.

The first type of a toggle latch is made for fixing cabinets. It is undersized and also cheaper but is less durable to handle strong vibrations. You can go with medium-duty latches if you have to work with a maximum load of not more than 2,500 kilograms. It will be more stable and won’t result in decoupling the latch. While heavy-duty latches are most suitable for a job that requires greater tensile strength, like huge vehicles, transport containers, and so on.

All in all, the size of a toggle latch will ensure the best performance in supporting a maximum load. The good news is that manufacturers will mention the tensile rating of the device to help buyers decide.

- Material Used

Apart from the tensile rating, the quality of a toggle latch also depends on how the tool was made. Manufacturers use a steel material to produce high-quality latches for industrial works. If you have to choose between stainless steel and zinc-coated steel, then the prior seems the best option for better durability.

- Price

Do not be deceived by the price when buying a toggle latch. Some pieces might be cheaper but this does not guarantee a good performance. The major risk of getting a cheap latch is its impact on the worker’s well-being. It may cause injuries, equipment damage, and even losing lives.

No worries as a toggle latch are not that expensive. It is additionally worth investing to take full advantage of accuracy at work.

- Maintenance

Toggle latches can last longer with proper maintenance. This tool is highly reliable when it comes to industrial jobs so make sure to use it correctly.

Know the proper ways to assemble the tool with the right fittings not to ruin its components. Regularly inspect the latch to ensure it is serving its purpose. The most important thing is that workers must know the certain latches for different applications. Lastly, keep the latch clean and lubricated after use.

Final Thoughts

A toggle latch is a simple tool that would benefit industrial workers a lot. There are factors every buyer should consider to end up with the right equipment. These include the price that may vary according to the product’s quality and performance. With Snapflat Latch, there will be fewer worries at the workplace knowing that the tool is durable.