What comes in your mind if you listen the word concrete? A wet mixture or the dry structure? Whatever, the discovery of concrete become the boon for the human beings. Nowadays in every structure, either tiny or huge, we can see extensive use of concrete as construction material in every sector.

Table of Contents

Concrete as construction material

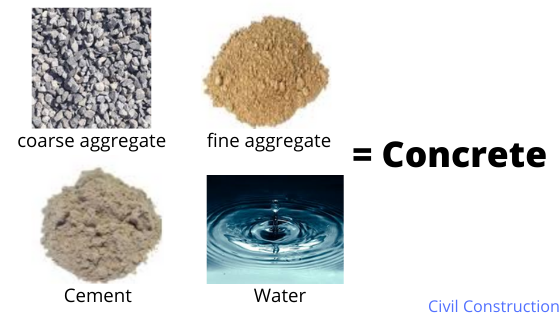

Concrete is a composite construction material consisting of binding medium and aggregate particles. Binding material is the product formed after the reaction of hydrated cement and water. Also there are some other binding materials such as lime for lime concrete, bitumen for asphalt concrete and so on. The commonly used cement in the construction field is Portland cement.

The aggregate particles includes the fine aggregates (sand) and coarse aggregates.

- Fine aggregate particle size less than 4.75 mm

- Coarse aggregate particle size more than 4.75 mm

The main constituents of concrete are cement, sand, aggregate, water and admixtures.

Types of concrete:

Based on design, concrete is of three types:

- Plain cement concrete PCC:

It has considerable strength on compression but very little strength in tension so it is used in member with only compression. PCC is normal used in minor works and in foundation before RCC works.

- Reinforced Cement Concrete RCC:

Simply, PCC with reinforcement is RCC. The reinforcement in RCC help to resist flexural and shear force. In construction, RCC is extensively used due to its property to withstand tension, excessive compression and shear.

- Pre-stressed concrete:

Pre-stressed means stress applied before its actual use. It is the type of concrete in which internal stress of appropriate magnitude are introduced so that the stress resulting from external loads are counteracted by the pre-stressed member to a desired degree.

In reinforced concrete member, Pre-stress is commonly introduced by tensioning the steel reinforcement.

Fig2

Based on purpose of construction:

These following types of concrete are manufactured for specific purpose to meet the requirement of specially constructed structure.,

1) Light-weight concrete

2) Heavy weight concrete

3) High strength concrete

4) Fire resistance concrete

5) Chemical resistance concrete

6) Temperature resistance concrete

7) Non-cracking resistance concrete

8) Polymer resistance concrete

9) Fiber reinforced concrete (FRC)

10) Self-compacting concrete

11) Crack-healing concrete

This types of concrete are made by using new technique use of admixtures, use of polymers and some other special construction technique.

Properties of concrete:

The four main properties of concrete are:

- Cohesiveness

- Workability

- Strength and

- Durability

- Cohesiveness

Cohesiveness is how well concrete holds together when plastic.

Cohesiveness is affected by:

- The aggregate grading

Graded Aggregate means that there is a range of size of aggregates, from large rocks to small sands. The aggregates with well-graded quality give more cohesive mix, but too much coarse aggregates give a boney mix.

- Water content

A mix that has too much water will not be cohesive and may separate and bleed.

2. Workability:

Workability is the properties of freshly mix concrete which determine how easy it is to place, handle, compact and finish a concrete mix. A slump test can be used to measure the workability of concrete.

Concrete is more workable construction material in most of the environmental condition. As compared to other material, there are large number of worker found familiar with concrete, not because it is widely used but they can learn with small invest of time with very less personal hazard.

3. Strength and Durability:

Concrete made properly well-graded is a naturally strong and durable material. Concrete is dense, reasonably watertight, able to resist changes in temperature, as well as wear and tear from weathering.

The density of concrete affects the Strength and Durability of the structure. Denser concrete is more watertight (or less permeable).

Factor affecting Strength and Durability of concrete:

a. COMPACTION: Compaction is process of removing the air from concrete and make it dense. Compaction is done manually or mechanically. In almost cases, different types of vibrator are used. Proper compaction results in concrete with an increased density which is stronger and more durable.

b. CURING: Curing is done to keep concrete damp for a period, to allow it to reach maximum strength. Curing is necessary to fulfill the demand of water for hydration. Longer curing will give more durable concrete. Curing in concrete should be done for more than 10 days.

c. WEATHER: The concrete will have higher early strength in warmer weather. To minimize the problem occurs due to evaporation, more amount of water is added which ultimately decrease strength. The cold weather concreting is also not feasible due to freezing problem.

d. TYPE OF CEMENT: The properties of cement of different types will affect concrete properties: ie how quickly or slowly concrete gains strength. Normally OPC cement is used for building construction but for huge structure construction PPC is more favorable. In OPC, different grade of cement (33,43 and 53) is available in the market.

e. THE WATER TO CEMENT RATIO Excess quantity of water or lack of required cement content indicates concrete will be weaker and less durable. Normally the water-cement ratio ranges from 0.4-0.5, depending upon different parameter such as workability, weather condition, strength and so on.

Grade of concrete

Grade of concrete is the designation of the concrete according to its cube compressive strength at 28 days. It is denoted by capital M and numeric value where M stand for mix and numeric value stands for characteristic compressive strength of the concrete in 28 days.

Here are some examples

M10 & M15 (use for base or leveling)

M20, M25 and above (use for all structural member such as in building slab, column, beam)

Grade of concrete is selected based on structural design requirements. Concrete mix is categories into two types : nominal mix and design mix.

Based on the nominal mix, different grade of concrete are

| Grade | Proportion |

| M5 | 1:5:10 |

| M7.5 | 1:4:8 |

| M10 | 1:3:6 |

| M15 | 1:2:4 |

| M20 | 1:1.5:3 |

| M25 | 1:1:2 |

The proportion given is the ratio of cement, fine aggregate and coarse aggregate. Above M25, we can’t use nominal mix, we should go through design mix.

- Mostly asked interview question, what does M20 stand for? (Note: the numeric value may be different)

In concrete, M stands for mix and numeric value 20 stands for characteristic compressive strength of the concrete in 28 days in N/mm2.

Q. Why is concrete as construction material used mostly in the world?

In every sector of construction either it is road or bridge, dam or hydro-power, irrigation canal or water supply, residential or commercial building, we can see huge use of concrete. The extensive use of concrete is due to following reasons:

- Strength and durability

The strength given by reinforced concrete is enough for any types of structure. It can resist all types of force and moment acting on the structure. If we talk about durability, it gives life-long durability that is more than 50-100 years.

2. Economical

Concrete is the most economical construction material with that level of strength and durability. It also makes the structure economical because it requires very little maintenance in its working period.

3. Easy to construct

In comparison to other construction material, it is easy to construct and also easy to learn about with small invest of time and low hazard.

4. Versatile in shape

Concrete is extremely versatile material so that it becomes possible to use in building, bridges, dam, tunnel, pavement, canal and many other construction.

5. Workable in field

No all structure are possible to construct from pre-cast material, but most are possible to cast in sites. It is highly workable construction material as compared to others.

6. Impermeability

Almost all structures require impermeability and the concrete fulfill this necessary condition. The water proof property of concrete can be realized from its possibility in dam construction, which is used to collect huge amount of water.

7. Consideration of energy and resource conservation

TEST of Concrete

- Lab test

- Crushing strength

- Flexural strength

- Air content

- Unit weight

- Field test

- Measure of consistency

- Work-ability (slump test)

- Compaction factor

- Concrete bleeding

- Temperature