Table of Contents

Two way slab design

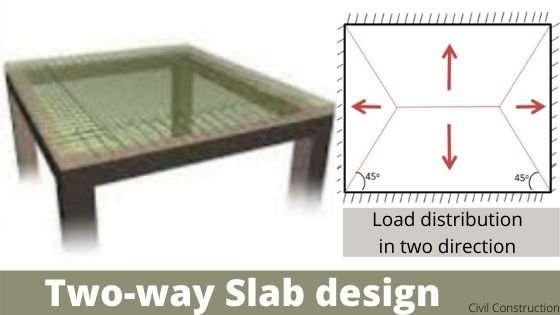

Two way slabs are those slab which are supported on unyielding supports on all four sides and the ratio of longer span to shorter span is less than 2. Unyielding support means supports with sufficient stiffness which may either beams or walls. The two way slab design is also designed as explained in IS codes.

Since load is distributed in both x and y direction, reinforcement have to be designed for both direction. Despite both being main reinforcement, reinforcement along shorter span should be kept in bottom layer.

For uniformly distributed loads over the span, the negative moment developed at the continuous support is 1.33 times greater than positive span moment. If there is no restraint at the discontinuous support, the negative moment developed is equal to zero. The possibility of partial restraint must be considered, even if no restraint, at the time of detailing.

Here we only talk about uniformly distributed load. For the calculation of maximum bending moment, IS 456:2000 Table 26 and 27 gives the coefficient of bending moment at span and support for given condition of boundary and aspect ratio. Aspect ratio is the ratio of effective longer span to shorter span.

Design cases for two way slab:

- Restrained slab

- Simply supported slab

Restrained slab:

Restrained slab simply means the slab which is supported on four sides with corner held down or the slab whose corners are prevented from lifting. The prevention from lifting may be due to monolithic casting with beam or construction of partition wall on the support. In this case, negative bending moment will be developed in the top face of the slab at the support both in continuous and discontinuous ends.

For restrained slab, IS 456:2000 Table 26 is used for bending moment coefficients. The maximum bending moment per unit width is given by,

Mx = αx w lx2

My = αy w lx2

Where, αx and αy are bending moment coefficient

W= factored load

lx = length of shorter span

In restrained slab, torsional reinforcement should be provided. Torsional reinforcement should be provided at all corner of discontinuous edges. It consists of two layer; top and bottom layer and reinforcement in each layer is parallel to the span of slab. The area of reinforcement on each layer should be 3/4th of the area required for maximum bending moment at mid-span. Only half of the torsional reinforcement required at the corner of adjacent discontinuous edge should be provided at corner of only one discontinuous edge.

The length of torsional bar is equal to 5 times the length of shorter span on both direction. The spacing should not be greater than 300mm.

Design steps of two-way slab:

Case I: Restrained slab

Step 1. Determine whether the slab is one-way or two-way slab by calculating aspect ratio.

If ratio of longer span to shorter span is less than 2, then it is two-way slab, otherwise one-way slab.

Step 2. Determine the minimum thickness of slab from serviceability criteria of deflection control.

It will be better to visit preliminary design of slab, which was discussed before in details.

Step 3. Calculate the effective span of slab from IS 456 clause 22.2 which is least of following values

- Center to center of supports or clear span + width of support

- Clear span + effective depth of slab

Step 4. Determine the total factored load due to live and dead load considering 1m wide strip.

Dead load is calculated from IS 875 part 1 and it mainly includes self-weight, floor finish and partition load whereas live load is calculated from IS 875 part 2.

Step 5. Calculate the factored design moment Mu and factored design shear force Vu.

The factored bending moment can be calculated by using the coefficient of bending moment from table 26 of IS 456:2000.

The factored shear force can be calculated by using the given formula:

Vu = w (r⁴/(1+r⁴))* lx /2 where, lx is length of shorter span.

Step 6. Check the thickness of slab.

The thickness of slab is calculated for given value of factored moment then check with initial value. The thickness calculated from factored design moment should be less than initial value if not, revise with greater depth.

Mu = Mu,lim = 0.36 fck b xu [d – 0.42 xu]

Step 7. Determine the area and spacing of main reinforcement in both direction.

The area can be calculated from given formula;

Mu = 0.87 fy As [ d – fy As/ fck b]

The spacing of main reinforcement bar should not be more than 3 times the effective depth of solid slabs or 300 mm whichever is smaller.

And the minimum area of main steel reinforcement is equal to 0.12% of bD.

Step 7. Check the adequacy of depth from deflection control criteria.

The thickness initially obtained is through different assumption and after calculating area of reinforcement provided, it is easier to calculate exact modification value. (IS 456:2000 clause 23.2.1)

The calculated ratio of shorter span to depth should be greater than initially obtained from assumed value.

Step 8. Check for shear

It is not necessary to check for shear in two-way slab. But it won’t be wrong if you design.

From IS 456:2000 clause 40.2,

The design shear strength Ⴀuv shall be less than equal to shear strength of concrete kႠuc

Step 9. Calculate the torsional reinforcement.

At the discontinuous corner, torsional reinforcement should be provided. It is provided in two layer. Each layer should have area per unit width equal to 75% of mid-span tension reinforcement for adjacent edge of a slab is discontinuous. But if only one edge is discontinuous then 37.5% will be okay.

Step 10. After designing all, all reinforcement drawing should be drawn.

Case 2: Simple supported slab

(No provision to resist lifting)

Most of the design procedures are same as above. The basic difference are as follows:

- There may be different during preliminary sizing of slab.

- Moment calculation

For the calculation of bending moment, the coefficient in table 27 of IS 456:2000 should be used. And there is almost zero bending moment at the support so there is no need of top layer reinforcement.

3. Torsional reinforcement

There would be no torsion arises in this cases so it is not necessary to provide torsional bar in this case.

ALSO VISIT